CZUR StarryHub™The fastest and most flexible way to run meetingEvery business is looking for future cost savings.

Purchase a StarryHub and efficiently setup and run a meeting.

Based on the reliable ANDROID operating system WiFi networking will already be familiar.

Connect 4 simultaneous WiFi devices, iOS and Android phones, Windows and Apple iPads and computers.

1 to 4 connected screens are displayed simultaneously.

All those facts and figures on your computer or network are

available to display as soon as sit down in front of the StarryHub™

Connect your cell phone to TV News or YouTube and screen cast to the StarryHub.

Online connections to several popular sharing programmes such as ZOOM bring to the outside world inside.

In Summary

It takes very little time to setup a StarryHub™.

No cables to store and carry beyond mains plug pack.

Easy moving logistics when changing your meeting site.

A big bright projected display for groups to see what's going on.

There is a couple of add-ons to sell you which add features.

Free Online training to show staff the full capability of a StarryHub meeting projector.

We think you will benefit from owning a StarryHub™ in your office (and/or home).

|

CZUR ET ULTRA SeriesAvailable nowSeptember 2025

ET 18 and ET 25 Pro have been our most sort after models.

The ET Ultra expands the range offering even higher resolutions

420 DPI, 40Mpixels images, ≤A3 scans

Call Hassan for details: +64 27 279 6001

|

Colortrac SmartLF ivo 6000SmartLF ivo 6000DIGITIZE LARGE FORMAT

ORIGINALS SAFELY

WITH CONTACT-FREE SCANNING

Introducing the Colortrac SmartLF ivo 6000

SmartLF ivo 6000’s contact-free scanning ensures no wear and tear of originals up

to 130 mm in height.

First-rate colour reproduction and expressive lifelike 3D surface

effects reproduces any original flawlessly.

This is the next step in high quality imaging.

|

Colotrac SmartLF SGi and SmartLF SCi scanners granted US FADGI approval.On April 2nd 2025 Colortrac announced US Federal Agencies Digital Guidelines Initiative (FADGI)

granted FADGI 3-star compliant recognition to these Colortrac scanners when using

Colortrac SmartWorks Imaging Software.

FADGI compliance is fast becoming a requirement in public sector procurement,

particularly in digitisation projects involving archives, libraries, and museums.

“Achieving the 3-star FADGI compliance means that our two leading scanner series now meet image

quality benchmarks used by the most demanding institutions without adding cost or complexity to the user,”

says Jacob Bendix, CCO and VP of Sales and Marketing at Colortrac.

The SmartLF SCi scanners with patented SingleSensor CIS technology and the SmartLF SGi CCD

scanners continue to be fast, reliable, and cost-effective. Now with the added option of providing

FADGI-compliant results when operated with the latest version of the SmartWorks Imaging software.

FADGI compliance

FADGI relies upon well-established practices, objective measurements, and quality assurance

methods to create accurate imaging. The purpose is to reduce variabilities that may be introduced by

the scanning process and human subjectivity.

FADGI is world-leading but compares to programs like

Metamorfoze and ISO-19264-1. ISO 19264-1 B and

Metamorfoze Light are comparable to FADGI 3-star, though they all get their results through different imaging approaches.

Colortrac includes SmartWorks TOUCH free of charge with each SmartLF SGI and SmartLF SCI Scanner.

However, achieving the FADGI 3-star compliance with a Colortrac SmartLF SCi or SmartLF SGi scanner

requires the professional SmartWorks Imaging software.

If you own Smartworks Imaging all you need to do is update it to the latest version.

If you wish to upgrade to SmartWorks Imaging you can get free trial version.

Call Hassan on 09 630 7871 to get this organised.

Colortrac celebrates 35 years of Capturing excellent images.

Colortrac is a pioneer of large format colour scanning and the leading innovator in affordable colour

and monochrome wide format scanning technology.

Our scanners are easy to use and produce great results, whatever your requirements.

Mandeno Electronics offer full sales and service support to all its New Zealand customers.

Colortrac was founded in UK in 1989 to develop digital large format scanning solutions.

The patented Colortrac invention ‘SingleSensor’ was a major gamechanger in the technology used to capture large format images.

|

Posital Wiegand SensorsThe Wonderful Wiegand Wire: Energy Harvesting, Motion Sensing and More Energy Harvesting, Motion Sensing and More

The “Wiegand effect” was discovered almost fifty years ago and has been used

successfully in several specialised applications. However, its full potential for energy

harvesting and signal generation has received only limited recognition. With recent

enhancements to the energy output from Wiegand devices and the emergence

of a new generation of ultra-efficient electronic chips for wireless communications,

the technology is showing significant promise, especially in the exciting new area of

the Internet of Things (IoT). UBITO, a member of the FRABA Group of technology

companies, is leading research and development projects aimed at fulfilling this

promise.

To promote this technology in New Zealand we are providing links to 2 YouTube videos.

1) The invention and mode of operation of the Wiegand effect.

Copy this link into your browser.

https://www.youtube.com/watch?v=rpdn9XNJBuc

2) This longer 2023 video talks of current and future Wiegand Technologies

https://www.youtube.com › watch?v=vkfeXi_WjQ8

Copy this link into your browser

3) Posital UBITO web for Wiegand Technologies

https://ubito.com/en/ubito-technology

This links allows you to see products you can purchase today.

If you are the inventive mind can we discuss and price Wiegand Sensors

for a new project. Phone me, Hassan, on +64 9 630 7871.

|

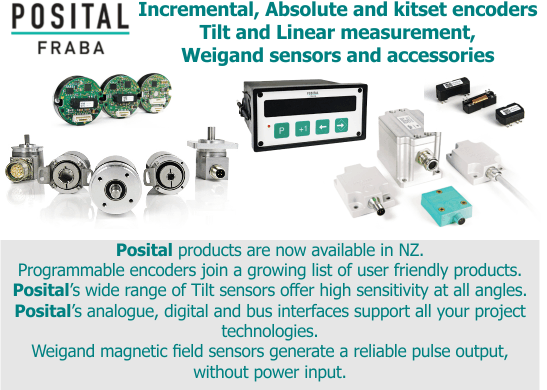

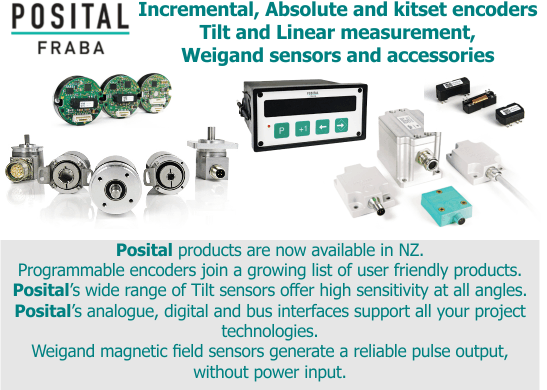

Posital Fraba

Excellent OEM products for New ZealandPosital offer a very wide range of options, proven and well establish overseas.

New Zealand engineers can consider this range with confidence.

How can we help introduce your company to Posital Products?

|

|  |  |  | Diggers and excavators Solutions from SIKO:

SIKO IMS360 and IMS360R level Sensors

SIKO MV3600MR Rotary encoders

SIKO MSAC200 magnetic and ring for motor feedback

| Loaders Solutions from SIKO:

SIKO IMS360 and IMS360R

SIKO WVR3500MR encoders

SIKO SGH10 and SGH25 hydraulic cylinder position

| High Lift loaders Solutions from SIKO:

SIKO IMS360 and IMS360R inclinometers

SIKO SG61 draw wire encoders

SIKO SGH10 and SGH25 hydraulic cylinder position

SIKO WV3600MR encoders

| Concrete Pump Truck SIKO !M360 and IM360R inclinometers

SIKO sgh10 Hydraulic Cylinder Position

SIKO WV3600MR encoder

SIKO MSAC200 magline motor position

|

SIKO safety rotary encoders.

The WH58MR rotary encoder is a magnetic safety rotary encoder with redundant position detection and hollowshaft,

which has been specially developed for use in mobile machines.

It can be used insafety-critical applications – up to performance level PLd. Thanks to its particularly robust design,

an optionally redundant CANopen or CANopen Safety interface, it is ideally suited for tough conditions in mobile machines.

- absolute redundant safety encoders

- CANopen Safety or CANopen redundant interface

- Can be used in applications up to performance level PLd

- Hollow shaft to ø 15 mm

- Salt spray tested housing available

- High EMC compatibility

- IP67 protection class

- With PURE.MOBILE technology

An additional feature is that extra internally mounted boards can add features.

Extension board DIP - programming board

Extension board IK1 - single axis tilt sensor

Extension board IK1R - redundant single axis tilt sensor.

Please click the image to download a data sheet. |

SIKO AutomationSIKO expands AP series with AP20 and AP20S modelsElectronic position indicator AP20Absolute spindle adjustments, integrated Industrial Ethernet interface SIKO advance the capability of AP series by introducing new BUS interface options. SIKO advance the capability of AP series by introducing new BUS interface options.

Absolute indicator with Industrial Ethernet interface which enables process-capable and intuitive positioning for manual machine adjustments. The display and evaluation of target and actual values ensures monitored format adjustment.

Profile AP20:

- Integrated Industrial-Ethernet-Fieldbus

- Backlit two-row LCD

- Display of target and actual value displays with integrated alignment

- Stainless-steel hollow shaft ø20 mm, up to ø25.4 mm as an option

- Robust sensor technology unit thanks to magnetic scanning

- User guidance through status LEDs

- IP53 type of protection, IP65 as an option

Electronic position indicator AP20S Absolute indicator with Industrial Ethernet interface which enables process-capable and intuitive positioning for manual linear or slider adjustments. The display and evaluation of target and actual values ensures monitored format adjustment. Absolute indicator with Industrial Ethernet interface which enables process-capable and intuitive positioning for manual linear or slider adjustments. The display and evaluation of target and actual values ensures monitored format adjustment.

Profile AP20S:

- Electronic position indicator with plug connection for magnetic sensor

- Integrated Industrial-Ethernet-

- Backlit two-row LCD

- Display of target and actual value displays with integrated alignment

- Display accuracy up to 0.01 mm

- Absolute function via internal backup

- Robust sensor technology unit thanks to magnetic scanning

- User guidance through status LEDs

- IP53 type of protection, IP65 as an option

Please click the image to read the SIKO Flyer |

January 2025Precision Wireless Tilt Systems Sherborne Sensors Wireless Tilt System (WTS) is designed to provide surveyors, geotechnical specialists and structural engineers with a complete measurement solution, without the cost, impracticality and system installation times of traditional wired methods. The WTS is a flexible, all weather, radio telemetry system that delivers highly accurate, remote angle, measurement data. Sherborne Sensors Wireless Tilt System (WTS) is designed to provide surveyors, geotechnical specialists and structural engineers with a complete measurement solution, without the cost, impracticality and system installation times of traditional wired methods. The WTS is a flexible, all weather, radio telemetry system that delivers highly accurate, remote angle, measurement data.

The WTS uses an advanced MEMS sensor to ensure high accuracy and maximum reliability. The multi-channel and distortion-free digital two-way telemetry system has a wireless range of up to 330ft (100m), 18 bit resolution and long battery life. Its robust design will ensure precision operation over many years in the most demanding environments.

Highway agencies, bridge and civil structure owners spend large revenues assessing structural health by visual or other types of consuming inspection methods of bolted and welded joints, together with other vital structural elements. Obtaining multiple readings to monitoring the entire structure can be costly and labour intensive. Using the WTS Wireless Tilt System, a single structure can be fitted with low power WTS Inclinometers at strategic points, thus helping to determine where weak points may be and when maintenance is required.

Furthermore, the WTS can be used to verify design calculations during the manufacture of new structures, providing valuable data for refining computer aided modelling of structural behaviour. A variety of complementary base stations and PC or hand-held data acquisition modules are available to deliver a complete measurement solution configurable to any type of structural health monitoring application. Contact us to find out more about how the WTS can support your business.

|

The A320 Series and A320L Series are high precision, servo balance ultra-low range accelerometers available in single and multi-axis configurations. They can be used in commercial, industrial, military and aerospace applications – from geophysical, seismic and civil engineering studies, to flight test monitoring and low acceleration analysis. The A320 Series and A320L Series are high precision, servo balance ultra-low range accelerometers available in single and multi-axis configurations. They can be used in commercial, industrial, military and aerospace applications – from geophysical, seismic and civil engineering studies, to flight test monitoring and low acceleration analysis.

Individual models are available down to ±0.1g full scale, with full range outputs of ±5Vdc or 4 to 20mA. Despite their low measuring range, the A320 and A320L Series sensors are extremely robust and highly resistant to mechanical shock. Sealed to IP65, they are housed in an aluminium corrosion-resistant casing and will withstand 1500g shock events, and operate reliably in temperatures ranging from -18°C to 70°C without significant degradation in performance. Electrical termination options are either a 6-pin, bayonet lock connector, or solder pins.

The A320 Series offers customers the ability to accurately measure ultra-low g events with a device that upholds the same high levels of performance and robustness as other Sherborne Sensor products. It complements our current accelerometer product line, and was developed as a standard product offering in response to customer demand.

|

January 2025World Magnetics aircraft pressure sensing.

Press Release:- World Magnetics has increased its range of pressure, vacuum and differential pressure switch products to include the VEP - Value Engineered Products aerospace series. Offering low pressure set points and high proof pressure, this series is ideal for aircraft applications such as landing gear and brake systems. Also available in a Low pressure differential and dual differential pressure model, these switches can be used for air speed and air flow detection when reliability and safety is paramount.

With a wide range of pressure ports and electrical connectors available, this series can be designed to meet most customers' specifications. Many of the switches in the series can be manufactured in Stainless steel allowing them to meet the FAA 15 minute flame test requirements.

This latest addition to the World Magnetics group compliments the existing product ranges which include the DesignFlex ultra sensitive pressure, vacuum and differential pressure switches as well as the Dietz industrial pressure switches.

The DesignFlex switches are available in a wide variety of housing, mounting, porting, diaphragm, and set point configurations covering a pressure range from 0.1” H2O to 50” H2O (0.25 to 125mbar). Application specific features on certain models include field adjustable set points, factory calibrated versions for tamperproof use and full military spec versions. The range is characterized by exceptionally long working life and extremely high reliability. Dietz air pressure switches are aimed at heavy industrial and extreme environmental uses. With a range of 0.05" to 40" H2O, the 170D model is an ultra-low differential pressure switch for applications such as trains, ships and construction equipment where shock and vibration resistance is of paramount importance. Dietz also produces an ultra sensitive pressure switch for extreme environment forced air systems, filters, blowers, and exhaust fans up to 2500 fpm.

World Magentics products are engineered and crafted at our global manufacturing facility and world headquarters located in Traverse City, Michigan, USA. Our passionate customer focus and complete end-to-end manufacturing capabilities provide many customer benefits, including simplified custom engineering; quick service; and high-quality, durable product solutions.

For further information please contact: hassan@mandeno.co.nz |

|

Energy Harvesting, Motion Sensing and More

Energy Harvesting, Motion Sensing and More

SIKO advance the capability of AP series by introducing new BUS interface options.

SIKO advance the capability of AP series by introducing new BUS interface options.

Sherborne Sensors Wireless Tilt System (WTS) is designed to provide surveyors, geotechnical specialists and structural engineers with a complete measurement solution, without the cost, impracticality and system installation times of traditional wired methods. The WTS is a flexible, all weather, radio telemetry system that delivers highly accurate, remote angle, measurement data.

Sherborne Sensors Wireless Tilt System (WTS) is designed to provide surveyors, geotechnical specialists and structural engineers with a complete measurement solution, without the cost, impracticality and system installation times of traditional wired methods. The WTS is a flexible, all weather, radio telemetry system that delivers highly accurate, remote angle, measurement data. The A320 Series and A320L Series are high precision, servo balance ultra-low range accelerometers available in single and multi-axis configurations. They can be used in commercial, industrial, military and aerospace applications – from geophysical, seismic and civil engineering studies, to flight test monitoring and low acceleration analysis.

The A320 Series and A320L Series are high precision, servo balance ultra-low range accelerometers available in single and multi-axis configurations. They can be used in commercial, industrial, military and aerospace applications – from geophysical, seismic and civil engineering studies, to flight test monitoring and low acceleration analysis.